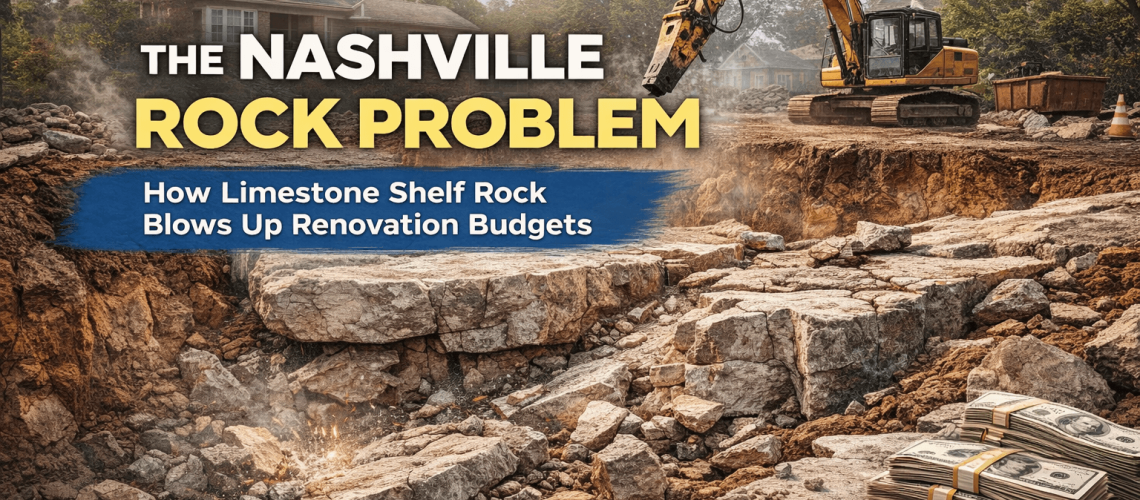

In Nashville, renovation budgets don’t usually explode because of bad planning. They explode because someone hits rock.

Middle Tennessee sits on extensive limestone shelf rock, and when it’s encountered during a renovation, addition, or new build, costs can spike fast. What looks like a straightforward project on paper can turn into weeks of redesign, specialty excavation, and unexpected engineering decisions.

Most home inspections never address this risk in a meaningful way. By the time it’s discovered, the buyer is already under contract—and scrambling.

What “Limestone Shelf Rock” Actually Means

Limestone shelf rock isn’t loose stone or scattered boulders. It’s continuous bedrock, often just a few feet below grade, especially in parts of Nashville.

Once excavation reaches this layer:

- Standard digging stops

- Heavy equipment or rock hammering is required

- Footing depths and foundation designs often must change

This isn’t rare or abnormal in Nashville—it’s geological reality.

Why Nashville Is Different From Other Tennessee Markets

In West Tennessee, construction challenges are typically soil-based:

- Expansive clay

- High moisture content

- Crawlspace-related movement

In the Nashville area, the challenge is often the opposite:

- Shallow bedrock

- Irregular rock shelves

- Limited ability to over-excavate or regrade

This difference matters because solutions that work elsewhere in the state don’t always apply here.

How the Rock Problem Blows Up Renovation Costs

When limestone shelf rock is encountered unexpectedly, costs increase for several reasons:

- Excavation changes – Standard excavation equipment may not work

- Design revisions – Engineers may need to alter footing or foundation plans

- Permitting delays – Structural changes often trigger re-review

- Labor escalation – Rock work is slower and more specialized

A project that was budgeted as a simple addition can quickly become a structural redesign.

Why This Often Isn’t Discovered Until It’s Too Late

Most inspections focus on what’s visible. Limestone shelf rock lives below the surface, and unless someone is thinking structurally, it’s rarely discussed.

Typical scenarios where this problem surfaces:

- Basement finishing

- Rear additions

- Garage expansions

- Tear-down rebuilds

- Major interior renovations requiring new footings

By the time rock is encountered, the buyer’s leverage is usually gone.

The Inspection Gap That Creates the Problem

When a standard inspector says:

“Recommend engineer if rock is encountered”

They aren’t wrong—but they’re also not solving anything.

That recommendation:

- Happens after discovery

- Comes after budgets are set

- Comes after timelines are committed

At that point, the damage is already done.

What a Structural Perspective Adds Up Front

A structural-focused inspection doesn’t wait for rock to be exposed. It looks at:

- Site grading and topography

- Age and style of the home

- Foundation type and depth indicators

- Nearby construction patterns

- Known limestone zones in Middle Tennessee

This allows buyers to understand risk before construction begins, not after.

Where This Matters Most in Nashville

Limestone shelf rock is especially relevant in:

- Older central neighborhoods

- Sloped lots

- Areas with shallow soil cover

- Homes undergoing expansion or redevelopment

In fast-moving Nashville markets, even a short delay can kill a deal—or turn a renovation into a financial stress test.

The Real Risk Isn’t the Rock—It’s the Surprise

Rock itself isn’t a defect. It’s a known condition in Middle Tennessee. The real problem is discovering it after decisions are locked in.

When buyers understand the likelihood of limestone shelf rock early, they can:

- Budget realistically

- Ask the right questions

- Avoid last-minute redesigns

- Keep projects—and deals—intact

In Nashville, structural certainty isn’t about peace of mind. It’s about avoiding preventable surprises.

And when surprises involve bedrock, they’re never cheap.