Zoned HVAC systems sound great on paper. Multiple thermostats, customized comfort, and better efficiency — at least that’s the pitch.

In the field, I see a different story more often than not.

Zoning only works when every component does its job. When one fails, the whole system starts lying to you.

Why Zoning Fails So Often

Zoned systems rely on:

- Motorized dampers

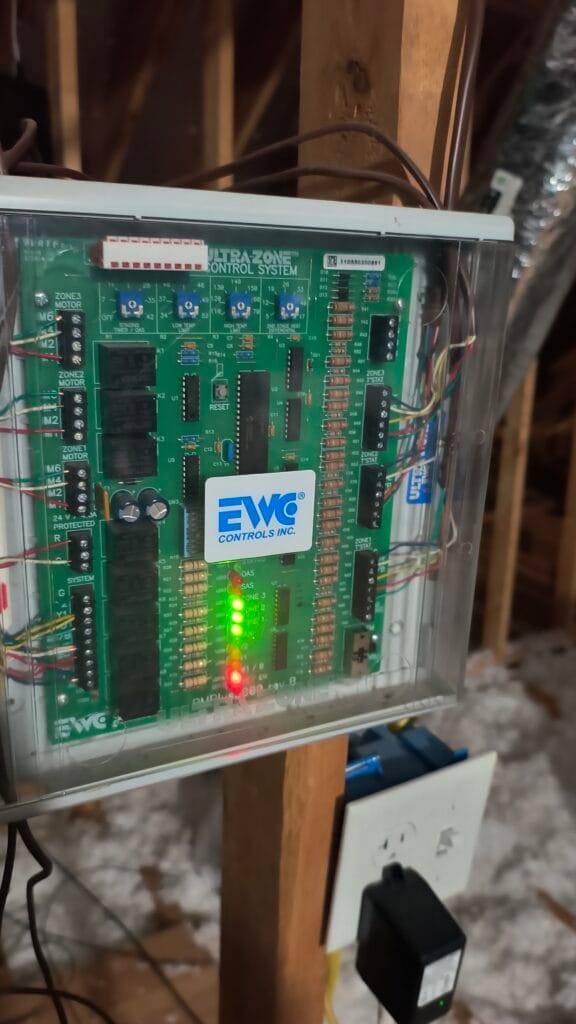

- Control boards

- Pressure relief strategies

- Correct duct sizing

That’s a lot of moving parts. And in larger Mid-South homes, shortcuts are common.

I’ve inspected plenty of homes where zoning was added after the fact without redesigning the duct system. That’s asking for trouble.

A Real Inspection Where One Damper Ruined Everything

I inspected a large home in Brentwood where the upstairs never cooled properly. Two thermostats said everything was fine.

Pulled a register and checked airflow — almost nothing.

Thermal camera showed cold air stacked up in the trunk line but not making it past the damper. Opened the damper access and found the actuator seized halfway closed.

That single failed damper was starving half the house, while the system kept running longer and harder trying to compensate.

What Failed Dampers Look Like in the Real World

When dampers fail, I usually see:

- Rooms that never match thermostat settings

- One zone overcooling while another overheats

- Excessive static pressure

- Whistling or banging in ductwork

- Short-cycling in mild weather

In Franklin, I inspected a home where a closed damper caused the blower to strain so hard it tripped the system repeatedly. Control board damage followed.

The Pressure Problem Nobody Talks About

Closing dampers increases static pressure. If the system wasn’t designed for zoning, that pressure has nowhere to go.

I’ve seen:

- Flex duct balloon like a trash bag

- Duct joints blow apart

- Blower motors fail early

- Noise complaints that never go away

Zoning without a bypass or proper design creates silent damage.

Why Thermostats Can’t Catch This

Smart thermostats report temperature — not airflow.

A thermostat can be satisfied while a damper is stuck, ducts are pressurized, and equipment is under stress.

That’s why I don’t trust the screen on the wall alone.

How I Inspect Zoned Systems

When zoning is present, I:

- Verify damper operation

- Check airflow at each zone

- Watch system behavior during calls

- Look for pressure-related duct issues

- Use thermal imaging to confirm delivery

If access panels are missing, that gets called out. You can’t maintain what you can’t reach.

What Buyers Should Understand

Zoning adds comfort when done right — and headaches when done wrong.

Failed dampers don’t announce themselves. They quietly increase wear, cost, and discomfort until something expensive gives out.

The Inspector’s Bottom Line

Zoned systems don’t fail because they’re a bad idea. They fail because they’re often installed without respect for airflow physics.

When dampers stop doing their job, the system still runs — just harder, louder, and shorter-lived.

That’s why I don’t just note that zoning exists. I verify that it actually works.