Structural issues in commercial buildings rarely announce themselves with dramatic failures. More often, they develop quietly—through incremental changes, added loads, and long-term stress that isn’t obvious during a casual walkthrough. By the time cracking looks “concerning” or doors stop lining up, the building has usually been compensating for a long time.

At Upchurch Inspection, structural evaluations in commercial buildings across the Mid-South are typically triggered not by collapse risk, but by uncertainty. Buyers sense something doesn’t add up, even if they can’t point to a single alarming defect.

Commercial Buildings Change Faster Than Their Structures Do

Most commercial buildings outlive their original purpose. Over time, they’re expanded, subdivided, repurposed, and reloaded in ways the original structural design never anticipated.

Inspectors often see:

- Warehouses converted to light manufacturing

- Retail buildings modified for heavier equipment

- Office spaces reconfigured with added mezzanines

- Medical or food facilities adding concentrated loads

- Storage or racking systems far denser than original assumptions

Each change may seem reasonable on its own. Structurally, though, load paths don’t reset just because use changes. They accumulate stress.

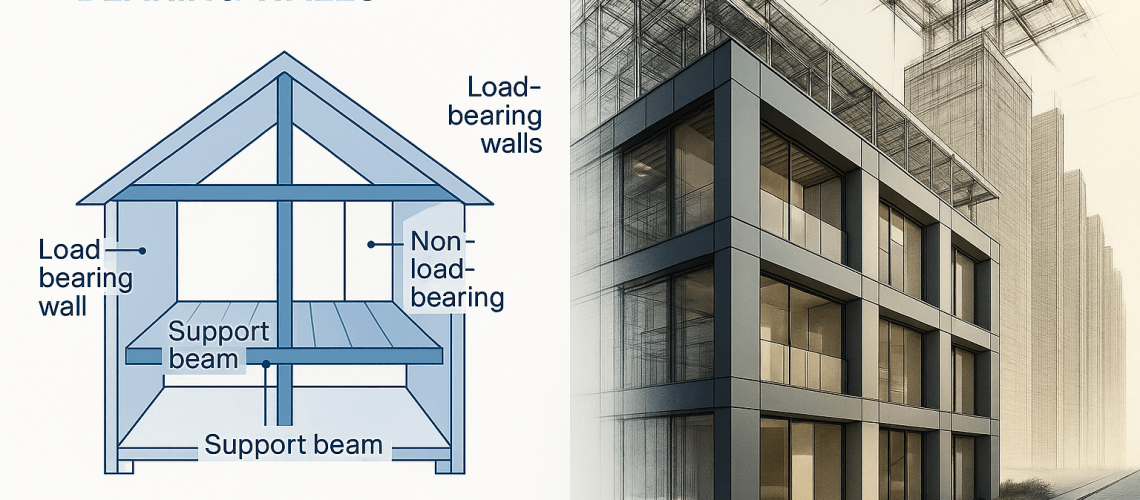

Structural Risk Is Usually About Redistribution, Not Failure

One of the most common misconceptions buyers have is that structural issues mean imminent collapse. In reality, most structural concerns involve load redistribution.

Inspectors pay close attention to:

- Beams or joists carrying more than originally intended

- Columns added or removed during renovations

- Bearing walls altered for layout changes

- Roof structure supporting additional equipment

- Floor systems absorbing point loads repeatedly

Buildings are remarkably forgiving—until they aren’t. Structural evaluations aim to understand how close a building is to that threshold, not whether it’s about to fail tomorrow.

Cracks Tell Stories—But Only If You Read Them Correctly

Cracking is one of the most misunderstood indicators in commercial inspections.

Inspectors don’t just note that cracks exist. They evaluate:

- Location and orientation

- Consistency across structural elements

- Relationship to openings, columns, or load points

- Evidence of repair or monitoring

- Whether cracking aligns with known modifications

In many Mid-South buildings, especially those on moisture-sensitive soils, some cracking is expected. The question isn’t whether cracks exist—it’s why they exist and whether they’re still evolving.

Added Equipment Is a Common Trigger for Structural Evaluations

Mechanical units, refrigeration equipment, solar arrays, signage, and industrial machinery all introduce new loads—often long after construction.

Inspectors look closely at:

- Rooftop equipment placement

- Load concentration over specific framing members

- Improvised supports or field modifications

- Evidence of deflection or vibration

- Repairs that suggest past stress

A roof or floor system that has “handled it so far” may already be operating beyond its intended margin.

Slabs and Foundations Absorb More Than Buyers Expect

In commercial buildings, slabs and foundations often act as silent shock absorbers for structural stress.

Inspectors evaluate:

- Differential settlement patterns

- Slab cracking tied to equipment or traffic

- Foundation movement near additions

- Repairs that addressed symptoms rather than causes

- Door and opening alignment issues tied to movement

In the Mid-South, soil behavior plays a major role. Structural evaluations often reveal that what looks like a framing issue is actually a soil–foundation interaction problem.

Why Structural Evaluations Are Often Recommended Late

Structural evaluations are usually recommended after a general inspection identifies signals, not conclusions.

These signals include:

- Modifications without documentation

- Inconsistent framing methods

- Long-span elements showing distress

- Repairs that lack explanation

- Planned use that increases load significantly

Inspectors don’t recommend structural evaluations casually. They recommend them when assumptions need confirmation—especially before a buyer commits to a use that stresses the building differently.

Structural Evaluations Clarify, They Don’t Condemn

A common fear buyers have is that calling in a structural engineer will “kill the deal.” In practice, structural evaluations more often save deals by replacing fear with clarity.

Evaluations can confirm:

- That existing systems are adequate

- That reinforcement is localized, not global

- That past repairs were effective

- That planned changes are feasible

- That risk is manageable and quantifiable

Uncertainty, not bad news, is what kills deals.

How Experienced Buyers Use Structural Findings

Seasoned buyers don’t expect structural evaluations to deliver perfection. They expect them to deliver boundaries.

They want to know:

- What loads are realistic

- Where flexibility exists

- Which changes are low-risk

- What upgrades would be required for expansion

- How structure affects long-term value

Structural findings inform pricing, design decisions, and future planning—not just immediate repairs.

The Practical Reality

Structural evaluations in commercial buildings aren’t about looking for failure. They’re about understanding how the building carries what it’s been asked to carry—and what it can safely carry next.

In older and heavily modified Mid-South commercial buildings, structure often tells the truest story of ownership decisions over time.

Inspectors who understand that story don’t just report cracks or deflection. They interpret load paths, modification history, and regional conditions to help buyers make informed decisions before stress turns into consequence.